Protecting Petrochemical Plants

Safeguarding Petrochemical Plants with Comprehensive Fire Protection

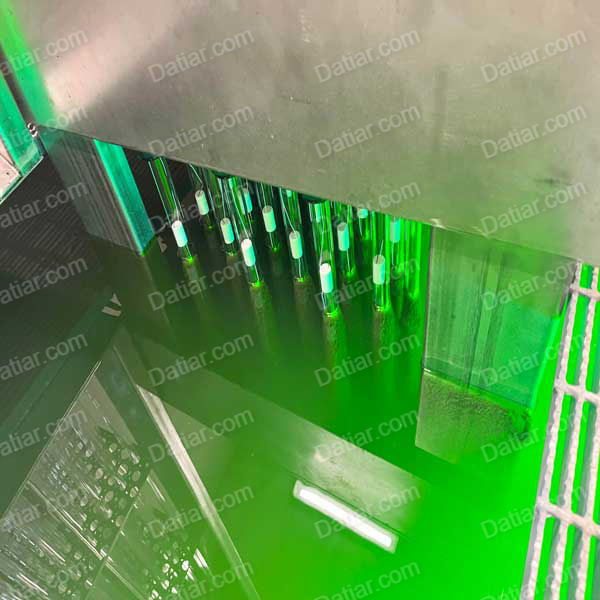

DTA Fire Protection offers an extensive array of specialized products tailored for Special Hazards Fire Protection. This diverse range encompasses gaseous and foam systems, flame detection solutions, and portable extinguishers. Our offerings are strategically designed to secure hazardous areas within Oil Refineries, Offshore Platforms, FPSO’s (Floating Production Storage and Offloading), and other critical environments. Our expertise spans specialty chemicals, foam and foam hardware, and fire-fighting services. Collaborating with Williams, a renowned name in emergency response for major petrochemical fires, and drawing on Tyco’s profound experience in foam fire fighting, we provide petrochemical and oil & gas customers worldwide with holistic on-site solutions, including emergency fire fighting services as needed.

The Significance of Petrochemical Plant Safety

Petrochemical and gas processing facilities inherently pose fire hazards due to their volatile nature. The potential repercussions of a significant fire disaster encompass social, political, financial, and ecological impacts, underscoring the paramount importance of safety considerations.

Fires in petrochemical and gas processing facilities can rapidly escalate temperature levels, facilitating rapid fire spread. This potentially catastrophic scenario was exemplified by the KHARG Island Oil Storage Terminal blaze. Such incidents emphasize the need for rigorous risk assessment and effective fire and blast protection measures to mitigate disaster consequences.

Combatting Hydrocarbon & Jet Fires

Among the most prominent threats faced by oil, petrochemical, and gas facilities is the risk of jet or spray fires. Jet fires involve forceful flames resulting from combustible fuel being forcefully released in a specific direction due to leaks or breaches in fuel containers. This creates intense localized heat, heightened heat flux, and turbulence. Such fires can erode fire protection measures, damage structural steelwork, and rupture vessels and pipe work more than non-hydrocarbon fires.

Properties of jet fires depend on factors like fuel composition and release conditions. While substantial research has been conducted, uncertainties remain. While the hazards are clear, the process of heat transfer from the fire to storage vessels isn’t fully understood. Active fire protection methods alone may not sufficiently control jet fires, necessitating passive fire protection measures. Passive measures focus on insulating structures from fire effects and preventing temperature escalation.

DTA Fire Protection is committed to developing and implementing cutting-edge solutions to combat fire hazards in petrochemical plants, ensuring enhanced safety and minimizing potential risks.