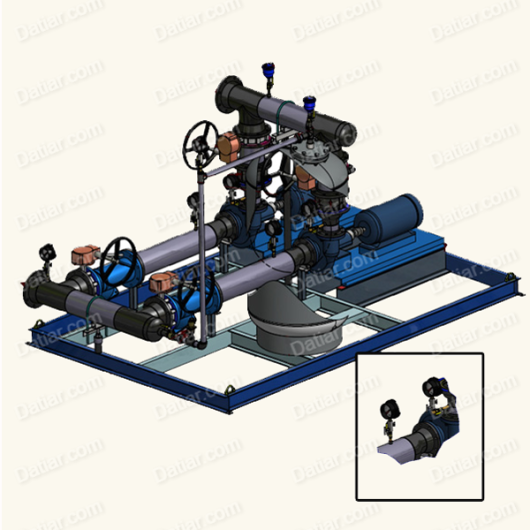

Medium Pressure Packaged Pump System

DANATIVARA introduces its Medium Pressure Packaged Pump System, thoughtfully engineered to efficiently transfer a diverse range of industrial liquids—such as water, hydrocarbons, and chemicals—between various locations. The comprehensive system boasts multiple horizontal multistage centrifugal pumps, electric motors, suction/discharge piping, valving, instrumentation, controls, all masterfully designed to minimize on-site assembly.

Advantages:

– Unified Responsibility: Single-source accountability streamlines management.

– Modular Efficiency: Pre-packaged modular design outperforms component-based site-built systems, leading to reduced overall project costs.

– Accelerated Deployment: Minimized field assembly time translates to quicker project delivery schedules.

– Thorough Pre-Shipment Testing: Comprehensive system function testing is conducted before shipping.

– 24/7 Customer Support

Adherence to Industry Standards:

– Vessel Compliance: Vessels are ASME Section VIII code stamped and National Board Registered.

– Piping Standards: Piping design aligns with ANSI B31.1/ANSI B31.3.

– Pipe Fabrication: Pipe fabrication adheres to ASME Section IX.

– Structural Integrity: Structural steel assembly is designed to meet AWS D1.1 specifications.

Standard Inclusions:

– Advanced Centrifugal Pumps: API 610 Horizontal Multistage Centrifugal Pumps.

– Enhanced Pump Bearing System: Choice of Sleeve/Ball Pump Bearing System or Sleeve Motor Bearing System with Ring Oil Lube.

– Diverse Pump Materials: Options ranging from Carbon Steel to Duplex Stainless Steel.

– Motor Enclosure Variants: Available choices include WP-II, TEFC (Totally Enclosed Fan-Cooled), TEAAC (Totally Enclosed Air-to-Air Cooled), or XP (Explosion-Proof) Electric Motor Enclosures.

– Duplex Pump Configuration: Provides 100% standby capacity.

– Motor Voltage Selection: Choose between 2300 Volt or 4160 Volt motor voltage.

– Comprehensive Instrumentation: Full pump/motor instrumentation includes Vibration, Temperature, Flow & Pressure Monitoring.

– Sturdy Base Design: Rigid structural steel base with curbed perimeter and drainage to minimize environmental impact.

– Piping Integrity Assurance: Hydrotesting guarantees the integrity of all piping.

– Robust Coating: High-quality industrial coating system ensures long-lasting durability.

Optional Additions:

– Flexible Configurations: Choose from Simplex & Triplex pump setups.

– Electrical Enclosures: All NEMA or IEC rated enclosures and components for Class 1, Div. 1 or Div. 2 electrical areas.

– User Interface: Panel view operator interface for enhanced user interaction.

– Advanced Control System: Microprocessor controller with integrated control software to monitor critical functions and provide comprehensive system control.

– Stringent Testing: Complete string test of the package before deployment.

Supplementary Services:

– Nationwide Support Network

– Expert Installation: Installation & supervision services.

– Comprehensive Solutions: Turn-key project execution.

– Flexible Financing: Equipment leasing program.

– Extended Assurance: Extended equipment warranties.