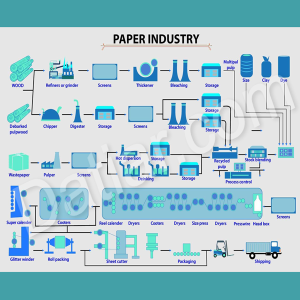

Pulp and Paper Industry

The pulp and paper industry consists of distinct sectors with varying wastewater profiles. These include pulp production, paper production, and paper recycling. Here, we break down the processes and wastewater treatment methods associated with each sector:

Pulp Production Process

The composition of wastewater pollutants in the paper industry hinges on the raw materials employed, such as wood, bagasse, hemp, and straw. Five primary methods are used for industrial pulp production, either with or without a bleaching process. Bleaching disrupts lignin and results in a brighter paper, with color influenced by the raw material used. This process, while enhancing paper quality, can be environmentally taxing due to the usage of chemicals like chlorine or chlorine dioxide.

Chemical Processes in Pulp Production

Two main chemical procedures are used for producing pulp for fine and print paper:

1. Kraft Process (Alkaline Process): Involves using NaOH or Na2S to break down lignin. Effective for various types of wood, this method produces an odorous byproduct (thiols and sulfides) and requires extensive bleaching.

2. Sulphite Process (Acidic Process): Based on acids, this process is more sensitive to impurities like branches and bark. While it offers process variations, it lacks the same level of efficiency as the alkaline process.

Water Treatment Approaches

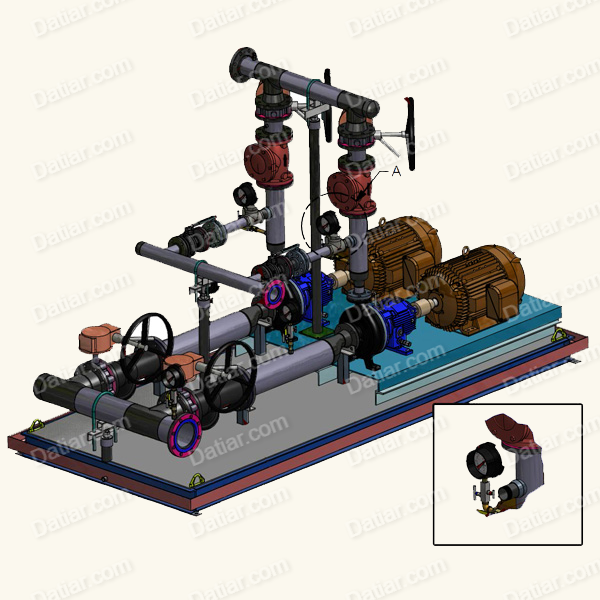

For the paper industry’s diverse water needs, several methods are employed:

– Demineralized Water Production: Achieved through ultrafiltration coupled with reverse osmosis or through counter-current regeneration (UFD process), ensuring good quality softened water.

– Ozone Treatment: Used for bleaching paper pulp and eradicating any residual chlorinated compounds (AOX).

– Wastewater and Sludge Treatment:** Includes physical/chemical processes for reducing suspended matter and phosphorus, biological pre-treatment for carbonaceous pollution elimination, and various biological and methanisation processes for diluted effluent and sludge management.

– MBR (Membrane Bioreactor):** Combines aerobic digestion with ultrafiltration membrane separation for advanced wastewater treatment.

– Full Range of Services:** Covers water treatment installation operation, maintenance, technical support, and leasing of mobile water treatment units for temporary requirements.

Benefits

The solutions provided by DANATIVARA offer numerous advantages:

– Guaranteed supply of process water in terms of both quantity and quality.

– Water savings and production of boiler supply water.

– Ozone treatment for paper pulp bleaching.

– Comprehensive treatment of wastewater, effluent, and sludge.

– Cost reduction through optimized processes.

DANATIVARA delivers an extensive array of water treatment solutions tailored to demineralized water production and the treatment of effluents from the paper industry.