Clarification

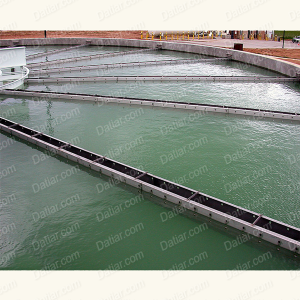

Suspended materials present in raw water sources are eliminated through various methods to render the water suitable for both domestic consumption and a majority of industrial applications. These suspended materials encompass two main categories: larger solids that can settle due to gravity alone, and non-settleable material, often in the form of colloidal particles. Their removal is primarily achieved through a combination of coagulation, flocculation, and sedimentation, collectively referred to as conventional clarification.

Coagulation is a process that involves neutralizing the charges on particles, rendering them no longer repellant to each other. This step is essential for addressing colloidal-sized suspended particles. Flocculation follows, which entails gathering the destabilized particles into larger clumps, known as “flocs.” Subsequently, sedimentation takes place, referring to the physical settling of particles that have undergone coagulation and flocculation. It’s important to note that sedimentation alone, without prior coagulation, only effectively removes relatively coarse suspended solids.

The following stages are crucial in the clarification process for aggregating particles:

– Coagulation: Achieved through the introduction of inorganic salts like aluminum or iron. These salts counter the charge on particles causing turbidity in raw water. They also facilitate the creation of insoluble precipitates that trap particles. Coagulation can also be accomplished using water-soluble organic polymers containing multiple ionized sites that neutralize particle charges.

– Flocculation: Enhances the agglomeration of destabilized particles into larger masses. High-molecular-weight, water-soluble organic polymers can be added to improve flocculation. These polymers bolster floc size by binding to charged sites and bridging molecularly.

To summarize, coagulation neutralizes charged particles to destabilize suspended solids. In most clarification processes, a subsequent flocculation step is employed. Flocculation initiates as neutralized or trapped particles collide and merge, forming larger aggregates. This natural process can also be augmented by incorporating polymeric flocculants.