Side Stream Filters

Side stream filters are as crucial to cooling towers as kidneys are to the human body. Given their significance, it is imperative that these equipment perform up to expectations without compromise. Any compromise in performance directly impacts the lifespan and efficiency of cooling systems.

When a cooling system influences the technical processes of an industry, the potential risks are even more pronounced. At DTA Co., our side stream filters are meticulously designed to consistently remove suspended solids, atmospheric dust, microorganisms, airborne debris, and particulates of rusted metal from heat exchangers.

DTA’s reliable side-stream filters yield several benefits, including reduced makeup water demand, diminished scaling and fouling across the system, extended intervals between cooling tower and refrigeration system maintenance, decreased reliance on chemical cleaning, controlled biological growth, and minimized maintenance downtime. By employing DTA Co.’s side-stream filters, you secure these substantial cost savings.

Key Features:

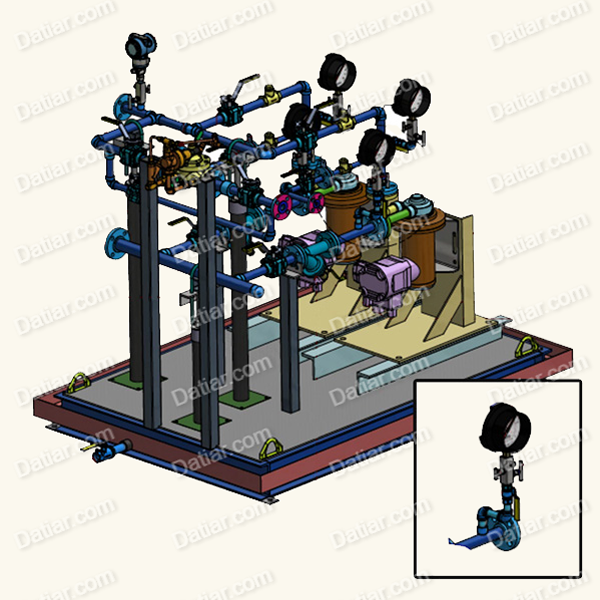

• Modular design – each plant functions as a standalone module.

• Pre-fabricated – pre-engineered and pre-assembled, with rigorous factory testing.

• Designed according to ASME/IS codes.

• Equipped with air scouring for high-flow pressure vessels.

• Engineered for pressures of up to 10 bar.

• Scalable – additional modules can be effortlessly integrated to augment capacities.

• Suitable for a variety of applications.

• All components boast proven quality.

• Exemplary workmanship evident in every detail.

• Utilizes high quality filtration media.

• Thoughtfully designed for easy maintenance.

• Minimal maintenance requirements.

Retrofit-ready for seamless integration with cooling towers* (*applicable to both side-stream and cooling tower pond configurations).

Capacity and Capability:

• Accommodates flow rates ranging from 1 M3/hr to 400 M3/hr.

• Handles inlet TSS (Total Suspended Solids) of up to 50 mg/L.

• Capable of managing inlet turbidity of up to 40 NTU* (*customized solutions available for up to 50 NTU).

• Offers filtration velocity of 12 to 30 M3/hr/M2.

• Filters particles with ratings of up to 20 Microns.

• Demonstrates high filtration efficiency – capable of removing up to 5ppm of Suspended Solids and up to 5NTU of Turbidity.

Applications:

• Effective removal of suspended solids.

• Efficient elimination of atmospheric dust.

• Removal of airborne debris.

• Extraction of particulates from rusted metals.

• Clearing of turbidity.

Benefits:

• Decreases demand for makeup water.

• Mitigates scaling and fouling across the entire system.

• Extends maintenance intervals for cooling towers.

• Reduces overall cooling system maintenance requirements.

• Lessens the need for chemical cleaning.

• Controls biological growth.

• Minimizes maintenance downtime.

• Achieves significant cost savings.