Carbon Dioxide (CO2) Fire Suppression Systems

Effective Fire Protection

Carbon Dioxide (CO2) is a versatile and effective known for its unique properties and widespread applicability. Here’s an overview of how CO2 fire suppression systems work and their key applications:

Properties of Carbon Dioxide:

– Colorless and Odorless: CO2 is undetectable by sight or smell, making it imperceptible to human senses.

– Electrically Non-Conductive: CO2 does not conduct electricity, making it safe for use around electrical equipment and systems.

– High Density: CO2 is approximately 50% denser than air, allowing it to create a suffocating blanket over a fire.

Operation and Effectiveness:

CO2 is stored in high-pressure steel cylinders as a liquid. When discharged, it rapidly expands into a gas. When applied to a fire, CO2 suppresses the fire by:

– Oxygen Depletion: CO2 displaces oxygen from the air, reducing the oxygen content to a level where combustion becomes impossible.

– Cooling Effect: CO2 absorbs heat energy from the fire, contributing to fire suppression.

– Minimal Residue: CO2 leaves no residue, ensuring minimal post-fire cleanup and preventing damage to sensitive equipment.

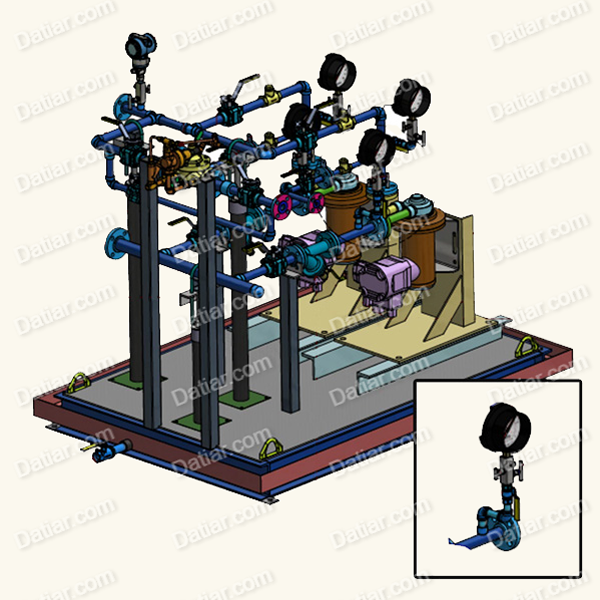

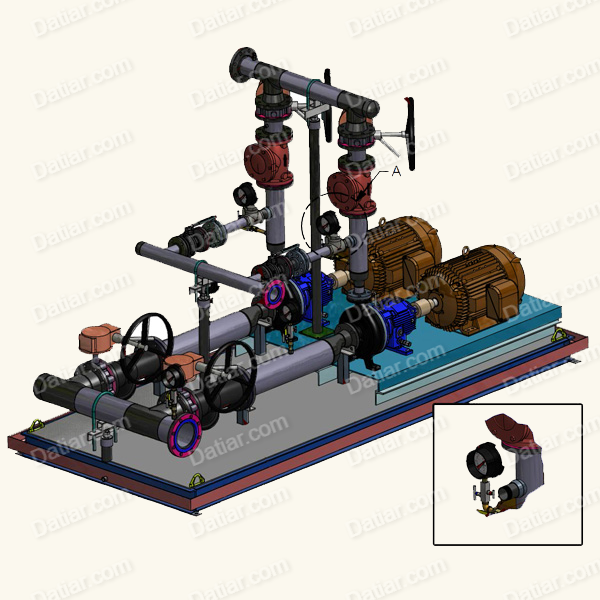

High Pressure and Low Pressure Systems:

– High Pressure CO2 Systems: These systems are designed for specific hazards and are effective in protecting critical areas. They discharge CO2 quickly and are suitable for applications such as engine rooms, electrical areas, and industrial ovens.

– Low Pressure CO2 Systems: These systems are cost-effective solutions for covering larger areas. They release CO2 more slowly, allowing for better distribution and coverage. They are commonly used in areas like flammable liquid storage, printing presses, and industrial process spaces.

Applications of CO2 Fire Suppression:

CO2 fire suppression systems find their applications in various industrial and commercial settings, including:

– Flammable Liquid Storage Areas: CO2 systems can prevent fires in areas where flammable liquids are stored.

– Printing Presses: The sensitive nature of printing equipment makes CO2 systems a valuable choice for fire protection.

– Industrial Ovens and Fryers: CO2 can effectively suppress fires in high-temperature environments such as industrial ovens and large fryers.

– Electrical Areas: These systems are suitable for electrical control rooms and other areas with sensitive electrical equipment.

– Turbine Driven Generators: CO2 systems can protect critical power generation equipment.

– Marine Applications: CO2 is commonly used on ships to protect engine rooms, paint lockers, and other critical areas.

– Spray Booths: Spray booths with flammable materials benefit from CO2 systems’ rapid fire suppression capabilities.

CO2 fire suppression systems play a crucial role in safeguarding areas where rapid and effective fire suppression is essential. Their ability to starve fires of oxygen and their versatility make them a valuable choice for a wide range of applications.