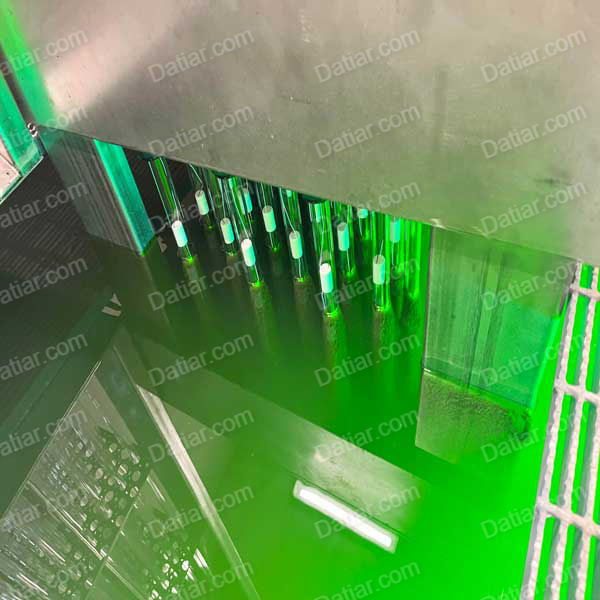

Activated Carbon Filters

Carbon filters are a type of media filter, yet they differ significantly from other conventional media filters due to their unique working principle. This distinction is often overlooked by many suppliers in this field. However, DTA stands out by recognizing this critical aspect, setting our activated carbon filters apart from ordinary and substandard alternatives. DTA’s activated carbon filters are equipped with virgin activated carbon media, boasting exceptional adsorption capabilities. Furthermore, these filters are meticulously designed to maximize the optimal utilization of the media. This results in an extended media life cycle, leading to enhanced output while consistently maintaining the desired water quality.

Our activated carbon filters are specifically employed to eliminate chlorine, organics, (THM’s), odors, and color from water. Additionally, this process contributes to an improvement in the overall taste of the treated water.

Key Features:

• Modular design – each plant functions as an independent module.

• Pre-fabricated – pre-engineered and pre-assembled, subjected to rigorous factory testing.

• Designed in compliance with ASME/IS codes.

• Operates within a working pressure range of 1.1 to 3.5 bar.

• Capable of handling pressures of up to 10 bar.

• Scalable – facilitates seamless module integration to enhance capacities.

• Durability is ensured.

• Utilizes components of proven quality.

• Exemplary workmanship evident throughout.

• Utilizes high-quality filtration media.

• Designed with user-friendly maintenance in mind.

• Minimal maintenance requirements.

• Retrofit-ready: can be seamlessly integrated into various water and wastewater treatment systems.

Capacity and Capability:

• Accommodates flow rates ranging from 1 M3/hr to 400 M3/hr.

• Achieves filtration velocities ranging from 6 to 18 M3/hr/M2.

• Effective Bed Contact Time (EBCT) spans from 2 to 30 minutes.

• Demonstrates an impressive 85% to 90% removal efficiency for chlorine, color, and odors.

Customizable Options:

• Auto valve equipped with a controller.

• Bottom connection featuring a header and lateral design.

• Platform, safety ladder, and Davit arm for enhanced accessibility.

Applications:

• Removal of chlorine, organics, tri-halo methane (THM’s), odors, and color.

• Enhancement of water taste.

• Effective pre- and post-treatment for reverse osmosis plants.

• Tertiary treatment in wastewater treatment plants.

• Facilitating septic tank expansion projects.