Heat Transfer

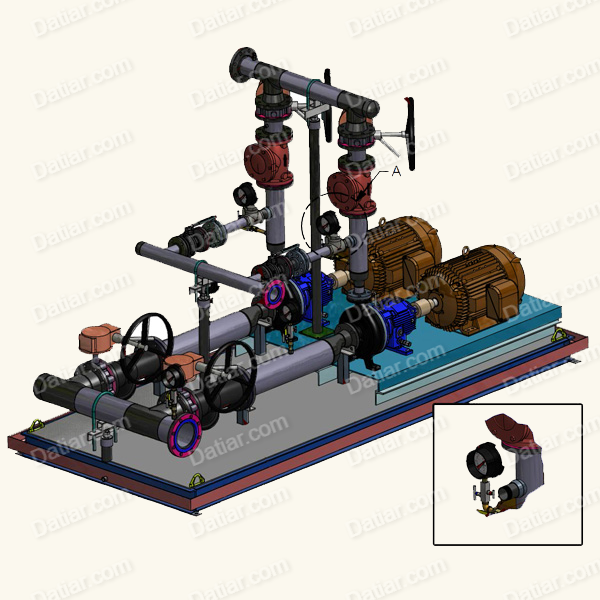

DANATIVARA Heat Transfer/Hot Oil Systems are designed to store and transfer heat transfer fluids for industrial heating applications. The heat transfer fluid is stored in an insulated vessel that is skid-mounted and elevated. Special high-temperature centrifugal pumps circulate the heat media fluid from the storage tank through various heating elements (electric process heater, gas-fired heater, or exhaust heat exchanger) to raise its temperature. The elevated temperature heat transfer fluid is used to safely heat a process system and is then returned to the storage vessel.

Benefits:

- Single Source Accountability: DANATIVARA offers a comprehensive solution for heat transfer systems.

- Pre-Packaged Modular Design: Reduces costs compared to component-based site-built systems and shortens project delivery schedules.

- Minimizes Field Erection Time: The modular design contributes to faster overall project completion.

- Complete System Function Testing: Ensures system reliability before shipment.

- 24 Customer Service: Provides ongoing support for customers.

Industry Standards:

- Vessels: ASME Section VIII Code Stamped & National Board Registered.

- Piping: Designed to ANSI B31.1/ANSI B31.3 standards.

- Pipe Fabrication: Complies with ASME Section IX.

- Structural Steel Assembly: Designed to AWS D1.1.

Standard Features:

- Special High Temperature Centrifugal Pumps: Designed to accommodate thermal growth.

- Thermal Pipe Stress Analysis: Prevents pipe rupture and extends equipment life.

- Cellular Glass Insulation: Aids in leak detection and fire prevention.

- Double Drop and By-Pass Expansion Tank: For venting of low boilers.

- INTEGRAHEAT TM Electric Process Heaters: Various configurations for different heat transfer fluids.

- On-Skid Starting Control Panel: Wired to electric motors.

Optional Features:

- Metal Fiber Filters: Prevent fouling of the system.

- Ladder and Platform: Provides access to the expansion tank.

- Air Cooler: Facilitates quick shutdown.

- API 610 Centrifugal, Canned Motor or Mag Drive Pumps: Different pump options.

- PLC Control System: Offers advanced control with data highway connectivity.

- Compliant Control Panel, Conduit, and Wiring: Adheres to relevant standards.

- Compliance with Plant/Engineering Specifications.

Additional Services:

- Nationwide Service Network: Offers support across the country.

- Installation/Training/Start-Up Supervision: Assists in system setup and operation.

- Equipment Leasing Program: Provides leasing options.

- Extended Equipment Warranties: Offers extended warranty coverage.

- “Aspen Plus” Process Simulation Software: Guarantees process conditions.