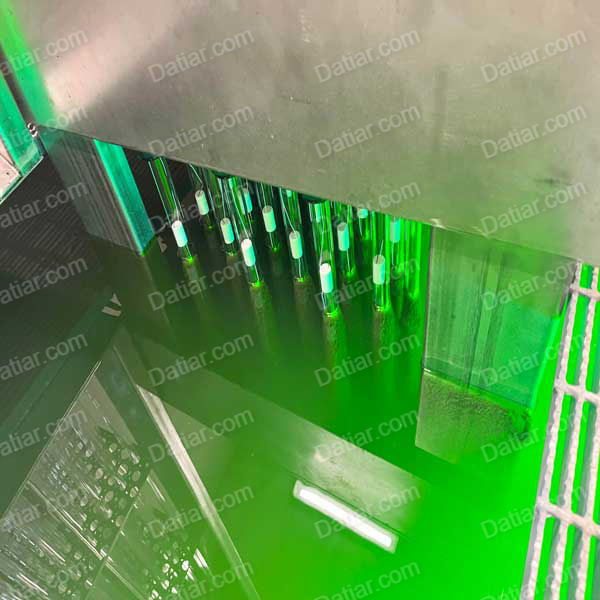

Custom Chemical Injection System

DANATIVARA Custom Chemical Injection Systems, are expertly crafted to provide a secure means of storing and injecting a diverse array of chemicals into process flow lines. These systems efficiently accommodate chemicals within skid-mounted, single or multi-compartment tanks. The chemical substances flow through gravity into metering pumps, which then elevate the pressure to meet the specific process requirements. The entire system is thoughtfully designed to minimize the need for extensive field assembly.

Benefits:

– Single Source Accountability:

– A pre-packaged modular design that costs less compared to component-based site-built systems, resulting in reduced overall project costs.

– Minimized field erection time, leading to a shorter project delivery schedule.

– Complete system function testing conducted prior to shipment, ensuring operational readiness upon installation.

– Continuous support with 24/7 Customer Service.

Adherence to Industry Standards:

– Vessels are Code Stamped ASME Section VIII and National Board Registered.

– Piping is designed according to ANSI B31.1/ANSI B31.3 standards.

– Pipe fabrication adheres to ASME Section IX requirements.

– Structural Steel Assembly conforms to AWS D1.1 specifications.

Standard Features:

– Multi-Point Injection of Chemicals facilitated through:

– Individual Metering Pumps.

– Multi-Headed Metering Pumps.

– Injection Rate Control Device (IRCD) with Metering Pump or Fixed Stroke Pump.

– Heavy Duty API 675 Metering Pumps & API 674 Reciprocating Pumps featuring:

– Packed Plunger Fluid End.

– Single Diaphragm Fluid End.

– Double Diaphragm Fluid End.

– Option for Electric Motor or Gas/Air Driven Pumps to suit operational requirements.

– Versatile Materials of Construction including Carbon Steel, 316SS, Alloy 20, and Non-Metallic options (PVC, Fiberglass).

– Rigorous Complete Factory Function Test to ensure performance and reliability.

Optional Features:

– Rack Mounted Bulkhead Controls for enhanced operator interface and ease of use.

– Integration of Double Diaphragm Fluid End Leak Detection for proactive maintenance.

– PLC Control System with Data Highway to facilitate sophisticated control.

– IEC/UL/CSA Listed Control Panel Assembly to meet international safety standards.

– Class 1, Div. 2 Hazardous Locations compliance for added safety in demanding environments.

– Comprehensive Factory Performance Test to validate system performance.

– Third Party Inspection by ABS, Lloyd’s, and DNV to ensure quality.

– Structural Analysis for robust design verification.

Additional Services:

– Comprehensive support services including Installation, Training, and Start-Up Supervision.

– Option for an Extended Warranty to ensure long-term peace of mind.

– Nationwide Service Network for ongoing assistance and maintenance.