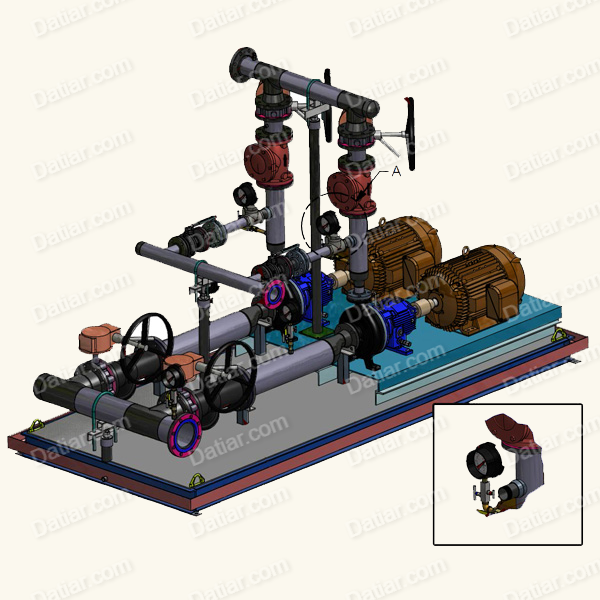

Standard Chemical Injection System

DANATIVARA Standard Chemical Injection Systems, offer a comprehensive solution for diverse liquid chemical treatment applications. These systems are thoughtfully predesigned, packaged, and meticulously tested to ensure reliable performance. The complete system includes essential components such as a chemical storage tank, two 100% metering pumps, instruments, tubing, valves, calibration column, and filtration.

Benefits:

– Single Source Accountability:

– A pre-packaged modular design that costs less compared to component-based site-built systems, resulting in reduced overall project costs.

– Minimized field erection time, leading to a shorter project delivery schedule.

– Complete system function testing conducted prior to shipment, ensuring operational readiness upon installation.

Adherence to Industry Standards:

– Chemical storage tank meets UN31A specifications.

– Piping/tubing designed in accordance with ANSI B31.1/ANSI B31.3 standards.

– Structural Steel Assembly conforms to AWS D1.1 specifications.

Standard Features:

– Flow rates ranging from 01 – 1000 gallons per hour (GPH).

– Operating pressures spanning from 50 – 1800 pounds per square inch gauge (PSIG).

– Utilization of robust API 675 Metering Pumps or API 674 Reciprocating Pumps, featuring:

– Packed Plunger Fluid End.

– Single Diaphragm Fluid End.

– Employing Totally Enclosed Fan Cooled (TEFC) Motors for reliable performance.

– Intermediate Bulk Container (IBC) with:

– Standard 304 stainless steel construction.

– UN31A rating for compliance and safety.

– Sloped bottom design for efficient drainage.

– Materials of construction primarily include 316 Stainless Steel, with options for Alloy 20 and Non-Metallic (PVC, CPVC).

– Enhanced durability and protection through the Offshore Ceram Kote Paint System.

– Equipped with Large Dial Liquid Filled Pressure Gauges.

Optional Features:

– Integration of High and Low-Level Switches for precise control.

– Option for Tank Gooseneck or Flame Arrestor to enhance safety measures.

– Selection of a 316 Stainless Steel Tank for specific requirements.

– Discharge Pressure Instrumentation for accurate monitoring.

– Start/Stop Station for convenient operation.

– Inclusion of a Skid Drain Pan for spill containment.

– Flexibility in materials of construction, including Alloy 20 and Non-Metallic (PVC, CPVC).

Additional Services:

– Comprehensive support services such as Installation, Training, and Start-Up Supervision.

– Option for an Extended Warranty to ensure long-term peace of mind.

– Tailored solutions with Customized Systems to meet specific project needs.