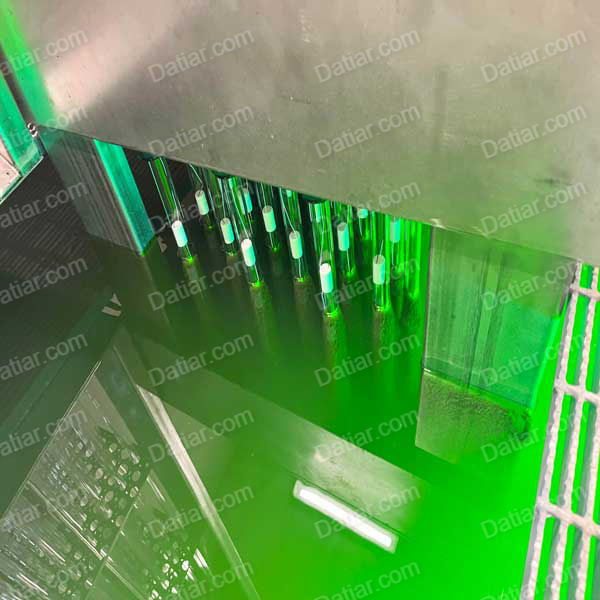

Electric Process Heating Systems

Electric Process Heating Systems consist of flanged heater bundles and control panels meticulously crafted in accordance with DTA’s technical specifications, aimed at effectively and efficiently heating both liquids and gases through electrical means.

Key Features – Process:

– DTA Electric Heater Process Sizing Software.

– DTA Industrial Grade Electric Process Heater & Control Panel Specification.

– Utilization of Aspen Simulation for Process Guarantee.

– Careful selection of Element Watt Density based on specific applications:

– Water: 45 watts per square inch.

– Fuel Gas: 23 watts per square inch.

– Air: 15 watts per square inch.

– Oil: 10 watts per square inch.

Key Features – Electrical:

– Safe operation within Non-Hazardous Area Classification.

– Equipped with Control Panel meeting NEMA 4/4X standards.

– Incorporation of Programmable Logic Control (PLC).

– Offers options for Outlet or Differential Temperature Control.

– Inclusion of Pressure Control mechanisms.

– Enhanced control via “Low Select” Over Ride Logic Control.

– Implementation of Process & Bundle PID Control Loops.

– Effective Load Management Control.

– User-friendly interaction through Human Machine Interface (HMI) with Touch Screen Graphic Color Display.

– Safety ensured with Finger Safe design.

– Detection of Ground Fault for added security.

– Prevents Heater Bundle Over Temperature through limit controls.

– Power control via Silicon Controlled Rectifier (SCR).

– Reliable electrical pathways through Rigid Galvanized “On Skid” Conduit.

– Precise wiring using Analog Wiring at 300 Volt, PVC Insulation, and 16 AWG Minimum.

– Control Power & Digital Wiring at 600 Volt, THWN Insulation, and 14 AWG Minimum.

– Power Wiring at 600 Volt XHHW-2 or THWN Insulation, with 12 AWG Minimum.

Key Features – Mechanical:

– Identity ensured with Stainless Steel Nameplate featuring Project Information.

– Sturdy foundation guaranteed with Heavy Duty All Welded Structural Steel Skid Base.

Additional Standard Features:

– Thorough Hydro Test conducted for Heater Bundle, Housing, and Piping.

– On Skid Megger and Continuity Test performed.

– Heater Bundle subjected to Megger, Resistance, and High Pot Tests.

– Control Panel undergoes Power and Control Circuitry Test.

– Simulated PLC Logic Test to verify proper functionality.

Adherence to Industry Standards:

– Compliant with NEC 500 for Control Panel design.

– Electric Heater Design adheres to established standards.

– Heater Bundle Terminal Housing meets CSA specifications.

– Conforms to ASME Section VIII & National Board Registration for Heater Housing.

– Conforms to ANSI B31.1 / ANSI B31.3 for Piping, Fittings, and Valves.

– Follows ASME Section IX for Pipe Fabrication.

– Structural Steel designed in accordance with AWS D1.1 standards.

Optional Enhancements:

– Available options for Hazardous Area Classifications:

– Class 1, Division 1

– Class 1, Division 2

– On Skid choice between Stainless Steel or Fiberglass Cable Tray.

– Offshore Paint option for added corrosion resistance.

– Incorporation of Heater Housing Insulation for enhanced efficiency and safety.